Sustainability & products

Multi-metal recycling is active resource conservation

Some challenges are easier to overcome with partners in the value chain. Sustainability Manager Kirsten Kück and Vice President Product Sales & Marketing Commercial Stefan Gröner, both of Aurubis, and Purchasing Manager Daan Kuipers of the Dutch cable manufacturer TKF met for a stakeholder dialogue and discussed CO2emissions, closing the loop, and why copper is here to stay.

Recycling: more copper, less CO2

The topic of copper recycling includes some interesting figures. The fact that recycling saves up to 85 % of the energy and about 60 % of the CO2emissions that arise in copper production from primary raw materials is especially exciting. Worldwide, the reduction amounts to around 100 million MWh of energy and approximately 40 million t of CO2eemissions, according to the International Copper Association. “To put it plainly, if we’re able to continue boosting recycling rates, the copper industry has the possibility to reduce energy consumption and the resulting CO2emissions,” says Kirsten Kück. “We have developed progressive technologies in the European copper industry that enable us to process a broad range of copper scrap while adhering to increasingly strict energy and environmental standards.” Aurubis alone hopes to reduce its CO2missions by 100,000 t, compared to fiscal year 2012/13, by implementing projects until 2023. During the reporting year, Aurubis reached 74 % of this goal, which is part of its Sustainability Strategy.

"If we’re able to continue boosting recycling rates, the copper industry has the possibility to reduce energy consumption and the resulting CO2 emissions."Kirsten Kück

Copper: a loyal companion over the centuries

Aurubis’ main metal is predestined for recycling thanks to its unique qualities. Copper is here to stay. Once it’s mined from the earth, it’s available for an infinite amount of time, from a metallurgical perspective. Between 70 and 80 % of all of the copper ever produced is still in circulation today. “Copper can be reprocessed over and over without a loss of quality or a decline in performance,” says Stefan Gröner. The product expert from Aurubis is convinced: “With our multi-metal recycling, we actively conserve resources and make ourselves less dependent on raw material imports from non-EU countries.”

Responsibility: a task for the entire value chain

The sustainable use of resources is a challenge for the entire value chain. “We can only take on this task with a concerted effort,” stresses Kück. Aurubis is developing individual logistical and technical concepts with its industry partners for this purpose. The goal: to reuse production waste or, even better, to avoid it altogether. Stefan Gröner believes that this is the responsibility of both the upstream and the downstream side: “The downstream industry has to be involved in this equation, for example when it comes to product design to enable recycling and when we’re talking about industry standards.”

Some examples of the collaboration along the value chain are closing-the-loop projects in which Aurubis takes back the production waste from its customers, making its customers copper scrap suppliers. Losses – in landfilling, waste collection, or processing – are a key reason why not all of the copper ever mined is in circulation today. “We have to find more efficient ways to retain as much material as possible in the cycle,” explains Gröner. The dialogue with our partners goes even further to make sure recycling is even better in the future. “This includes working together with our customers and manufacturers of end products on a common understanding of how easily recyclable end products could look – that is, design for recycling.”

Partnerships: collaborating with our customers

One of our partners on the customer side is cable manufacturer TKF in Haaksbergen in the Netherlands. Focusing on innovative, high-end technologies in the telecommunications, construction, and industrial solutions sectors, the company discusses topics such as the use of renewable energies and responsible consumption with Aurubis within the scope of stakeholder dialogues. TKF and Aurubis work together to identify ways to contribute to the UN Sustainable Development Goals (SDGs), which TKF has also used as a basis for its reporting since 2017. “Environmental, social, and corporate governance criteria are fully incorporated in our strategy,” explains Purchasing Manager Daan Kuipers from TKF. “Together with our partners in the supply chain, we look for opportunities to make a joint contribution to the UN Sustainable Development Goals.” He values this dialogue and the collaboration with Aurubis a great deal.

“Our stakeholders can directly or indirectly influence our activities. Being in constant dialogue with them enables us to share and test our vision, our strategy, and our expectations with them. This always gives us very valuable feedback that we use for further improvements,” says Kuipers. “We can rely on Aurubis 100 % when it comes to fulfilling its obligations. And we consider Aurubis an industry leader when it comes to sustainability. Our discussions have proven that environmental topics are very important to Aurubis. We like these open discussions and the way we do business together.”

One key element of the collaboration between Aurubis and TKF is a closing-the-loop project. “We try to establish closing-the-loop systems with as many of our customers as possible,” says Gröner. “Bringing these loops full circle needs to be the norm in the industry. Ultimately, everyone benefits.”

"We can rely on Aurubis 100 %. And we consider Aurubis an industry leader when it comes to sustainability."Daan Kuipers

Rising demand: red gold with a green conscience

“As an integrated copper producer, Aurubis has set the objective of producing even more copper from secondary materials, especially complex recycling raw materials,” says Gröner. “We already produce more than one out of three cathodes from recycling materials, and the trend is rising.” Gröner can imagine copper products made completely of recycled material creating a new market for sustainably produced metals and metal products at some point down the road. “Industry still has trouble paying a surcharge on a metal that’s traded as a commodity on the exchange. However, the trend towards a sustainable, transparent value chain, which is evident in some industries and driven by consumers, can’t be overlooked.” Kuipers also believes that demand for recycled copper could increase and that the market could ultimately honor this development. “Yes, this demand will grow for sure. Our customers’ mindset is also changing with regard to using primary materials. At TKF, we have set clear targets for the recycling of different materials, including copper.”

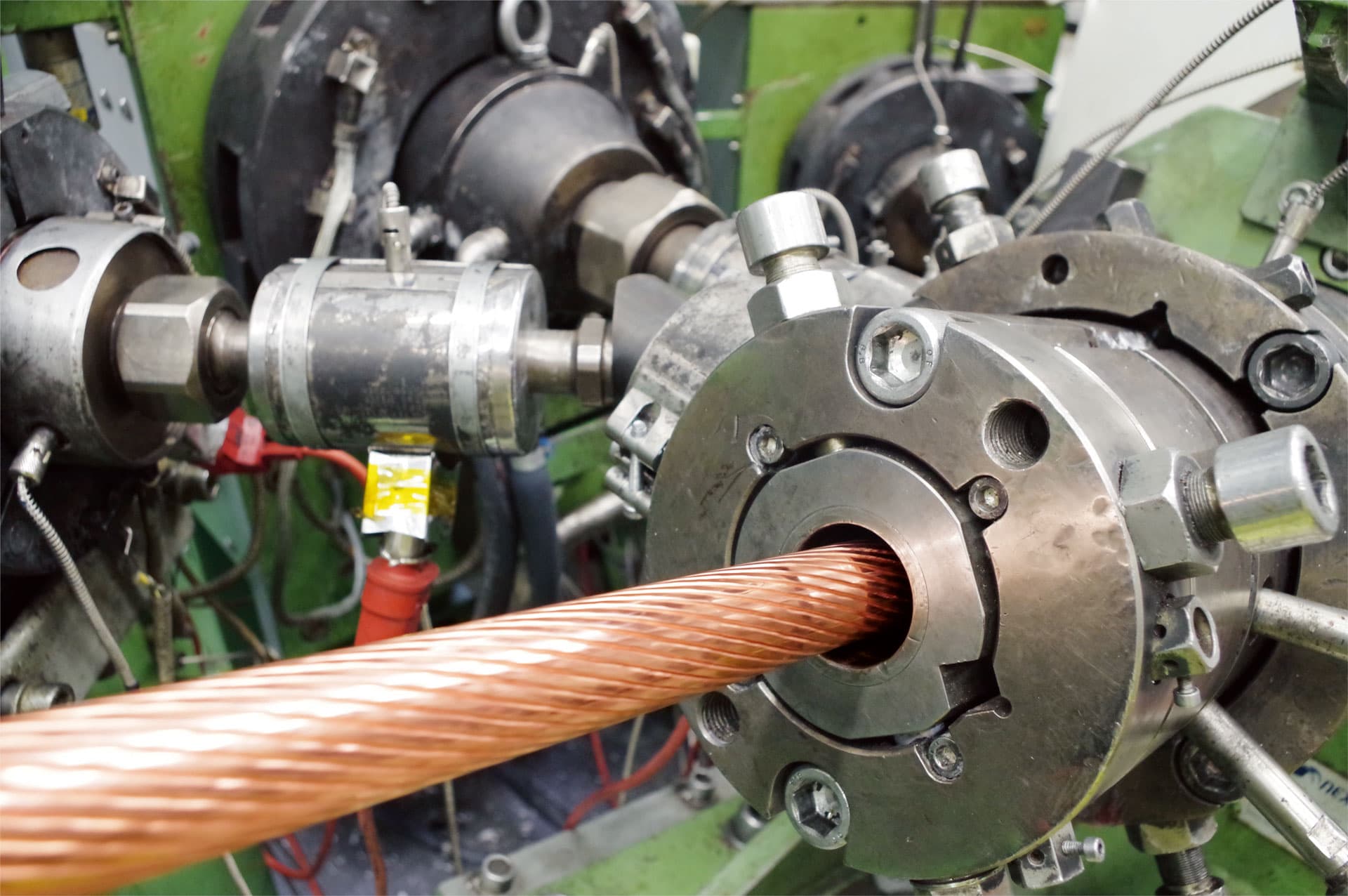

TKF processes the copper it sources from Aurubis into medium- and high- voltage cables, for example. The company provides connectivity solutions and an extensive portfolio of cables, systems, and services.

Coming full circle: using copper to reduce CO2

The market’s influence on the responsible use of resources is also apparent in megatrends such as electromobility and renewable energies. In this context, Aurubis contributes to reducing future CO2emissions not only by producing metals with recycling materials, but also with its finished products. For instance, copper plays a key role when it comes to renewable energies and thus the energy shift as a whole. “According to the Deutsches Kupferinstitut, energy systems for renewable energies require up to twelve times more copper than conventional energy systems,” says Kück, “because copper typically improves energy efficiency.” As an example, a ton of copper used in rotating machinery – such as an electric engine or a wind turbine – saves up to 7,500 t of CO2eemissions during its life cycle. That’s a pretty interesting figure, too.

The interior of a wind turbine, which requires about 5,000 kg of copper.

1 According to the Copper Alliance/ International Copper Association.