Recycling qualities

Our credo: the more complex, the better

Slags, electronic scrap, and filter dust – Andreas Nolte recognizes the intrinsic value of things that most people would consider waste material. He knows where the real treasures can be found in recycling – and how to recover them.

Up to 80 trucks make it to the Lünen site on a normal day. This is where Aurubis processes the lion’s share of its recycling raw materials. Each year, the entire Aurubis Group receives a total of about 28,000 truckloads of 25 t each. Roughly 30 to 40 % of the material is simple copper scrap, while the rest is made up of complex compositions. The latter is increasing steadily. While this development entails challenges in processing, it also provides opportunities on the earnings side.

Scrap metal: made in Europe

Aurubis sources most of its recycling raw materials directly from Europe. The metal processor relies on a network of specialized companies that concentrate on collecting, sorting, and preprocessing these materials. Aurubis also obtains materials directly from its industrial customers. “Our supplier portfolio comprises companies numbering in the mid-triple-digit range,” says Nolte. “They all undergo our Business Partner Screening process. We don’t buy anything from anyone we don’t know.”

The suppliers receive the delivered material directly from consumers in some cases – from recycling centers, community waste collection points, or scrapyards. Metal that lands in the normal garbage by mistake also makes its way to Aurubis in the form of metallic residues in ashes from waste incineration. Likewise, metallic remnants and waste products that collect in production processes are also redirected to the value cycle through different recycling methods, if possible. This cyclical approach doesn’t just make good business sense, it’s also part of the Aurubis Sustainability Strategy.

From sampling to production

Every day, an unknown value of raw materials is delivered to Aurubis. The processing steps such raw materials have to undergo depend on their unique material properties. The company’s Sampling department first determines what these properties are. Depending on the material at hand, employees from the department take representative subsamples, which they analyze to establish the metal content. Only then can they assess the actual value of the raw materials.

About 65 employees in Lünen alone are involved in accepting, weighing, examining, and, ultimately, accurately analyzing and sampling raw materials. “Our credo: the more complex, the better – because we’re particularly good at that,” says Nolte. Take memory cards, for example: while the first hard drives were as big as wardrobes and just as heavy, modern memory chips are the size of a fingernail. The tiny components are made of a combination of different metals – a growing challenge for sampling and, subsequently, recycling.

Sampling is followed up by the material preparation step. For example, electronic scrap is initially preprocessed – that is, shredded and sorted. Aurubis operates a special plant at the Lünen site for this material preparation. “This allows us to remove substances such as aluminum or some plastics – large volumes of which disrupt our recycling process – immediately at the beginning of the process,” says Nolte. “It’s important that we put together the right mixture of recycling raw materials early on in the process.”

Aurubis processes recycling materials that couldn't be any more different or complex.

From “A” as in alloys to “Z” as in zinc scrap

Aurubis processes recycling materials that couldn’t be any more different or complex. These include various qualities of copper scrap, from production waste to gutters to alloyed scrap. The company processes industrial residues such as slags; lead, electroplating, and wastewater slimes; catalysts; filter dust; shredder materials; complex metal concentrates; and precious metal-bearing residues. More and more, Aurubis is also being offered complex electronic scrap such as circuit boards and old appliances from external preparation processes in the recycling industry.

Hidden treasures

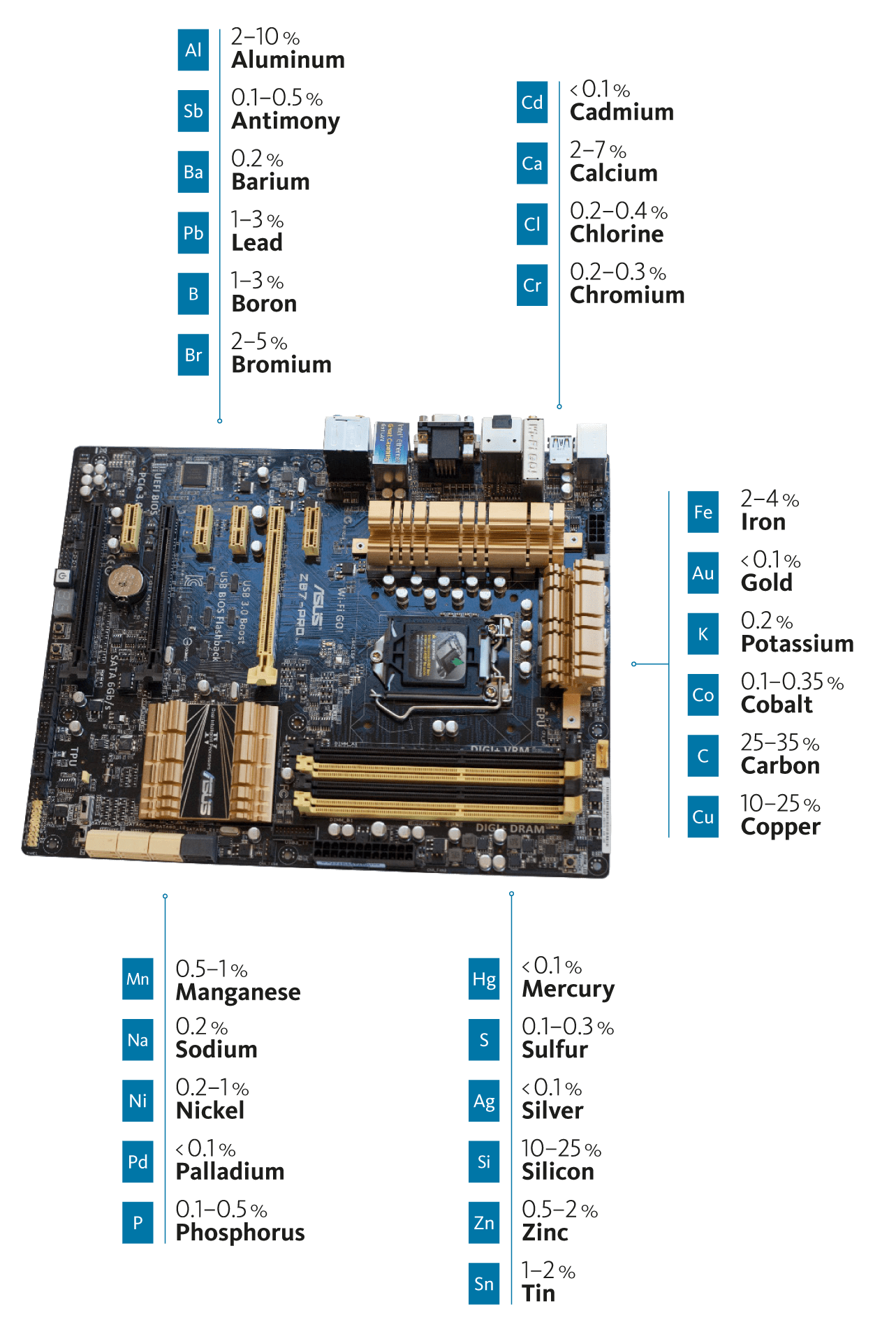

E scrap contains many substances – a typical analysis of circuit boards

Site specializations

Every Aurubis smelter site has a different focus: while Lünen handles and processes slimes, dust, and complex electrical scrap, the Bulgarian site in Pirdop primarily uses pure copper scrap as cooling scrap. The facility in Olen inputs copper scrap as one of the three main components in the smelting process. In contrast, Hamburg recycles both electrical scrap and pure scrap metals. Recycling is thus a topic at every site in different ways. “Thanks to this integrated smelter network, we can recover metals like gold, silver, tin, and lead from supposed waste materials. For example, a ton of cell phone scrap contains up to 300 grams of gold,” says Nolte. “In light of declining resources and growing mountains of waste, our expertise is now in higher demand than ever. And we don’t just deal with our main metal, copper, but use its property as a collector of many other accompanying metals to recover a total of 19 metals and metal compounds.”

Highest-level certification

“Our multi-metal recycling is also multi-certified,” says Nolte. For outsiders, some of these certifications sound cryptic: certification in accordance with the German Waste Management Facility Directive in connection with the Electrical and Electronic Equipment Act, for instance, or processor and end user audits pursuant to WEEELABEX/CENELEC. But they can be summed up as follows: Aurubis works reliably according to the highest standards in Europe – from material acceptance to production.

A huge shredder dismantles complex materials such as computer parts in Lünen. A misting machine controls the ensuing dust.